CNI is pleased to announce that we have teamed with

Aida-Dayton. For over 85 years, AIDA has worked

to become the leading global builder of the most comprehensive

line of metalforming and stamping presses in the industry,

and recognized as a premier provider of smart stamping solutions

and non-traditional technology innovations.

Aida ServoPro™

Let the Revolution Begin.™

Introducing ServoPro™: Everything You Know About Metalforming

Just Got Reprogrammed.

ServoPro technology is the first fundamental change in the

forming industry in more than 30 years. The key is the

high torque/low RPM servomotors–big motors–designed and

built by AIDA specifically for press applications. Connected

directly to the crank, they provide the precise accuracy and

reliability you expect of AIDA. The result is improvement in

almost every critical area of press performance. Completely

programmable stroke. Unlimited flexibility of part runs. More

press for your dollar. And it’s just the beginning.

For complete information about how the ServoPro system can enhance

your metalforming applications, visit the Aida-Dayton website

Single Point Gap Frame Presses:

NC1 Series

|

Single Point Gap Frame Press

35 to 250 metric tons

The

NC-1’s welded steel frame with cast iron slide and cast steel

bolster provide minimal angular deflection resulting in increased

die life.

Features:

- Six-point flat gibbing of the cast iron

slide ensures precision guiding

- Fastest hydraulic overload protection system in the

industry, HOLP

- Mechanically interlocked wet clutch and brake

- Automatic self-monitoring lubrication system

- Power slide adjustment with locking system

- Auxiliary timing switches for automation

- Adjustable air counterbalance system

- Up to 30% Less Angular Deflection Under Load

- AIDA® ACCESS Control

|

|

Two Point Gap Frame Presses:

NC2 Series

|

Double Crank Gap Frame Press

110 to 250 metric tons

The NC2 is ideal for general stamping

applications requiring high accuracy.

Features:

- Two-point counter-rotating crank shaft system reduces

side thrust

- Six-face slide gib structure minimizes

front-to-back and left-to-right movement

- Fastest hydraulic overload protection system in the

industry, HOLP

- Wet clutch and brake

- Minimal overall clearances to reduce the effects of

breakthrough

- AIDA® ACCESS Control

|

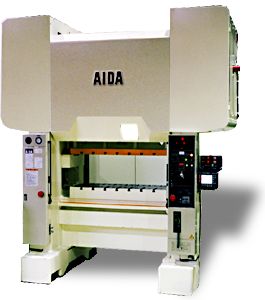

Straightside Frame Presses:

NCS Series

|

Straightside

110 to 300 metric tons

The NCS uses a unique integrated

straightside frame to eliminate angular deflection inherent

in C frame presses.

The increased frame rigidity helps provide excellent reliability,

accuracy, and increased die life, while reducing vibration

and noise for an improved work environment.

Features:

- Two-point counter-rotating crank shaft system reduces

side thrust

- Six-face slide gib structure minimizes

front-to-back and left-to-right movement

- Fastest hydraulic overload protection system in the

industry, HOLP

- Wet clutch and brake

- Minimal overall clearances to reduce the effects of

breakthrough

- AIDA® ACCESS Control

|

|

High Speed Progressive Die

Presses: HMX U Series

|

High Speed Progressive Die Presses

30 to 200 metric tons

The HMX U provides more speed and stroke length than any

other comparable press, with speeds up to 1500 spm.

Features:

- Lowest deflection characteristics of any high speed

press

- Unsurpassed bottom dead center control through use of

combined bearings

- Passline guiding

- Optional GuideMax® posts and bushings

- Dynamically balanced

- Integral vibration damping system

- Micro-inching control for set-up

- Slide quick opening for die access

- Thermal Control

- AIDA® ACCESS Control

|

Double Crank Straightside

Presses: SMX Series

|

Double Crank Straightside Press

300 to 2000 metric tons

The SMX series provides the accuracy and reliability required

for the automotive, appliance, furniture or any other industry

that involves massive parts and corresponding stroke lengths.

Features:

- Advanced link motion (optional) with

a reduced draw speed

- Wide suspension point spacing

for increased eccentric load capability

- Tie-rod tightened frame, increasing rigidity and precision

- Eight-point square slide guide that limits lateral and

longitudinal movement

- Minimal overall clearance to reduce the occurrence of

breakthrough

- Overload protector utilizing

an advanced metal seal design, offering fast response

time for protecting your tooling & press

- Wet-type clutch/brake for less friction disc wear

- AIDA® ACCESS Control

|

|

Large Capacity Transfer Presses

|

Large Capacity Transfer Press

300 to 4000 metric tons

The TMX series builds on AIDA’s

strength in manufacturing transfer presses of various sizes.

With high capacity to handle a wide range of applications,

the TMX is custom designed to your specifications, and can

include a link drive for deep draw and forming applications.

Features:

- Optional link drive

- Tie-rod type frame for excellent rigidity

- 8-point square slide guide minimizes longitudinal and

transverse movement

- Fastest hydraulic overload protection system in the

industry, HOLP

- Minimal overall clearance derived from high-precision

components

- Wide suspension point spacing

- AIDA® ACCESS Control

|

Progressive Die Presses:

UMX Series

|

Progressive Die Press

60 to 110 metric tons

With the UMX, high utility makes

a great leap forward to improve the productivity of small

precision parts. The slim design makes it ideal for the next

generation of press facilities.

Features:

- The advanced single-piece frame structure and unyielding

suspension mechanism makes high precision a reality

- The super-strong 6-face long guide maintains high rigidity

- Control system (optional) monitors die height changes

due to heat displacement

- Intelligent controls improve operability and workability

- Flexibility to match production floor needs

- No pit required

- Fastest hydraulic overload protection system in the

industry, HOLP

- Wide-spaced slide connections

- AIDA® ACCESS Control

|

|

Straightside

Unitized Frame Presses: NSU Series

|

Straightside Unitized Frame

200 to 400 metric tons

Built with rigid construction for multi-purpose applications.

Features:

- Rigid, unitized frame for rock-solid durability

- Eccentric gear design is ideal for high performance

dimension work in the appliance, HVAC, furniture, hardware

and other industries

- AIDA's unique Hydraulic Overload Protection (HOLP) is

standard

- 0.001"/ft bed and slide defection rating under full

load

- AIDA® ACCESS Control standard, or

Honeywell WINTRISS SmartPAC and the Link Systems Omni Link

5000 are available.

|

|